Turbine Nano Bead Mill

- BrandLeadmark

- ApplicationPaints/Inks/Coatings/Pigments/dyes/pulp/minerals/Ceramic/jet/cosmetics/life sciences/microbiology/agrochemicals/semiconductor

- Voltage/Hertzcustomized

- Motor Power5.5-90KW

- Motor TypeExplosion proof

- Speed0-1600r/m

- AdvantageTotal Explosion proof

- Frequency converterYES

- Vessel Capacity2-60L

- chamberTurbine kind

- cooling systemYES

- Zirconium bead size0.1-1.8mm

- Zirconium bead quantity70-80%

- With diaphragm pumpYES

- Grinding Fineness200nm-300nm

- Mechanical CoolingYES

- Mechanical SealingYES

- MaterialSS304/alloy steel/high molecular material

- production capacity(kg/h)50-1500L

- Zirconium beadExcluded

- ColorCustomized

- Sea PortGuangzhou/Shenzhen

- Lead time30days

- Warranty year1

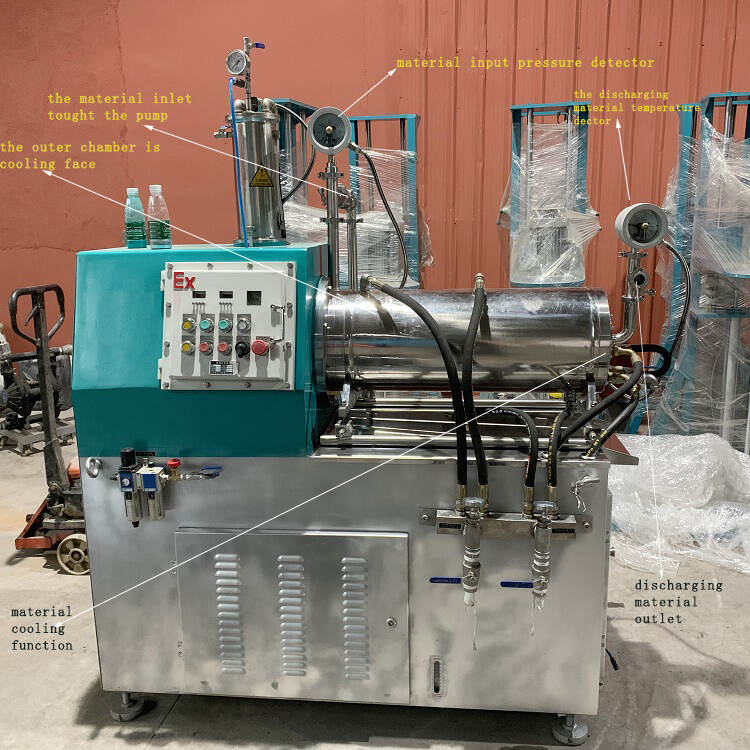

Horizontal Turbine Nano Bead Mill for making Paints/Inks/Coatings/Pigments/dyes/pulps/minerals/Ceramic/jet/cosmetics/lifesciences/microbiology/agrochemicals/semiconductor

●Designed for running in single/multi-pass or circulation, with a constant efficiency in both processes for the achievement of narrow

particle size distributions;

●Turbine accelerator a powerful, hydraulic movement of the beads which guarantee a high and constant energy input;

●The mill has a low energy uptake due to its efficient energy input;

●Ability to handle low to highly viscous products;

Ideal cooling properties allow the processing of temperature

sensitive products;

● Gentle processing as a result of hydraulic movement of the beads.

Cooling detector

Cooling detector is a part of the cooling system,You can control the speed of the cooling book cycle

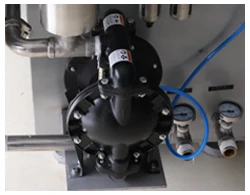

Material Pump

Material pump is part of the material system ,can control the speed of the material by the control pannel

Explosion proof Electricity Panel

The indicator light on the control panel can also be used to check whether the material works under normal conditions

PERFORMANCE ADVANTAGE

●Much higher throughputs;

●Better ability to process highly viscous products;

●Longer lifetime of the screen;

●Improved ability to handle foaming products;

●Ability to grind in the nanometre range;

●Simple handling of the machine during the production and the maintenance;

●Possibility for fast product changes at low costs;

●Optimal suitability for the pass mode and the circulation mode.

APPLICATION DOMAIN:

●Paints and varnishes ●Coatings ●Jet ●Ceramic ●Pharmaceutical

●Agrochemicals ●Paper industry ●Microbiology ●Printing inks

●Pigments and dyes ●Automobile coatings ●Semiconductor ●Food industry

●Cosmetics ●Life sciences ●Filling Materials

Guangdong Leadmark Chemical Machinery Co., Ltd. is specialized in the design, development, production and sales of chemical machinery and complete sets of non-standard chemical equipment. Our company mainly products: high-speed dispersing machine, vacuum dispersing machine, high-viscosity mixer, horizontal sanding machine, basket sanding machine, three-roller machine, reaction kettle, high-speed dispersion kettle, multi-functional dispersion Chemical equipment such as kettles and stainless steel pull cylinders. Our company have rich production experience, strong technical force, strong R & D team, flexible design and production of various standard and non-standard equipment base on the needs of users, our company adheres to the integrity-based, quality assurance, service quality, multi-variety Operating characteristics and service concept .Our professional and experienced service engineers will give you the most professional solutions and services. Our company is based on the principle of "customer first, quality and service". In additon,we could supply products with high quality and reasonable price.

RECOMMEND

High Speed Disperser

$ 1800.00 ~ $ 12500.00

Vacuum Disperser

$ 5685.00 ~ $ 11816.00

5-25L Iron Bucket Filling Machine

$ 3500.00 ~ $ 5900.00

Double Shaft Mixer

$ 1040.00 ~ $ 23835.00

Vacuum Mixer

$ 10400.00 ~ $ 26175.00

Emulsifying Machine

$ 5600.00 ~ $ 11268.00